RS "Rittel Services ..... keeping machines running longer!"

Atmospheric plasma spraying (APS)

A versatile high-performance process

High-quality, reliable and durable – atmospheric plasma spraying, APS for short, is a versatile thermal spraying process.

With that we process high melting point materials – from ceramics via metals to tungsten.

Processes with highest process temperatures

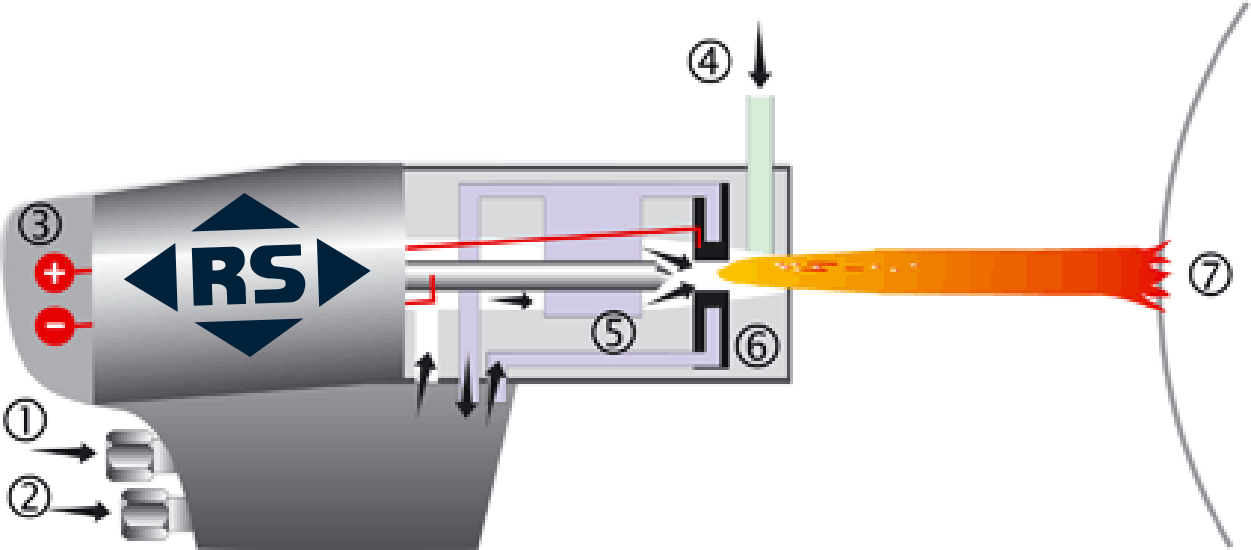

We generate the plasma by means of a burning electric arc in which gases are bundled, such as argon, helium, nitrogen, hydrogen or mixtures of them.

The gases are at the same time dissociated and ionized – with high discharge velocities and temperatures of about 16,000 degrees Centigrade. During recombination they give off their thermal energy to the spray particles.

Inside or outside the spray gun, powder is injected that melts due to the high temperature of the plasma jet.

The plasma jet is finally accelerated onto the workpiece surface to be coated.

(1) Inert gas

(2) Cooling water

(3) Direct current

(4) Pulverized spraying material

(5) Cathode

(6) Anode

(7) Workpiece.

APS for ceramic layer systems

APS is particularly well suited to the application of ceramic layer systems, but we can also apply hard metal or metal coatings by means of APS.

Our APS experts will be pleased to answer all your questions regarding atmospheric plasma spraying.

Do you need further information?

+49 2043 97 34 0 info@rs-rittel.de

Do you need further information?

+49 2043 97 34 0 info@rs-rittel.de

What can we do for you?

Do you need further information?

+49 2043 97 34 0 info@rs-rittel.de

Kompetenzen

RS Rittel

Stollenstraße 21

45966 Gladbeck

E-Mail: info@rs-rittel.de

Fon: | +49 2043-97 34 0 |

Fax: | +49 2043-97 34 89 |

© 2018 RS Rittel GmbH